The 5 Imperatives Manufacturing Leaders Must Embrace in the Age of AI

Artificial intelligence is changing how manufacturers see, measure, and manage performance. Every factory now sits at the intersection of data, decisions, and disruption. Yet as Vineet Khanna, former Global Head of Supply Chain at Nestlé, explained during The Future of Manufacturing: Scaling Operational Excellence for Growth, Productivity, and Profit — the opening session of the Advisors Value Creation Series — the technology itself is not the revolution. The real transformation lies in how leaders think.

AI amplifies what already exists. It strengthens organizations with clarity, discipline, and aligned decision-making, but it exposes those ruled by fragmentation and noise. It accelerates excellence and confusion alike. The challenge, therefore, is not to acquire new tools but to evolve leadership. To compete in this new era, manufacturing leaders must move beyond operational control and embrace enterprise thinking, seeing their plants not as cost centers, but as engines of financial performance.

From Vineet’s insights, five imperatives now define the modern manufacturing leader.

1. Lead with Clarity, Not Complexity

Manufacturing has always lived inside complexity. Supply chains stretch across continents, product portfolios expand endlessly, and every system produces more data than people can interpret. AI doesn’t eliminate that complexity; it magnifies it. The best leaders respond by simplifying. They bring focus to the noise, aligning their teams around a few clear indicators that truly define success.

As Vineet reminded the audience, many organizations are drowning in dashboards but starving for meaning. Clarity is not about fewer metrics, it’s about metrics that matter. The leaders who excel are those who translate technical indicators into financial ones, linking visibility on the line to visibility in the P&L. When operators and executives share a single definition of value, technology becomes an enabler of speed, not confusion.

2. Treat Technology as a Value Instrument

In too many companies, digital transformation has become a contest of tools rather than a pursuit of value. Vineet urged leaders to resist that impulse. AI, automation, and analytics are not outcomes; they are instruments designed to uncover financial potential. When guided by business logic, they reveal hidden capacity, shorten cycle times, and defer capital expenditure. When detached from financial clarity, they create pilots that inspire presentations but rarely profit.

True leadership begins with a simple but demanding question: How will this improve the business? The best executives don’t start with algorithms or dashboards; they start with the P&L. They use digital tools as a means to convert complexity into cash flow, and data visibility into better, faster decisions. That mindset separates transformation for show from transformation for growth.

3. Build Capability Before Connectivity

AI connects machines, but it cannot connect intentions. Many organizations are racing to digitize every process before they have built the capability to interpret what the data reveals. Vineet was clear on this point: technology can show you where you are losing value, but only capable people can recover it.

The factories that sustain performance are those that invest in capability before connectivity, teaching teams to see losses as financial opportunities, to understand their role in the enterprise equation, and to act with ownership. This is structural resilience. A connected operator who knows why their task matters to EBITDA is more valuable than an automated line nobody knows how to improve.

4. Create One Language of Value

One of Vineet’s most resonant messages was that the language of business is money. Manufacturing transformations fail not because the ideas are bad, but because the departments don’t speak to each other. Finance works in ROI, operations in OEE, and technology in uptime, three dialects describing the same ambition but never converging.

The best leaders unify those voices into a single narrative of value. They quantify every improvement in cash, cost, and capital. They make operational excellence measurable in financial terms, which creates alignment across functions. Once that alignment exists, AI and data can move freely across the organization because everyone evaluates success through the same lens. When the factory floor and the boardroom speak the same language, transformation stops being a project and starts being a system.

5. Scale Operational Excellence Before Innovation

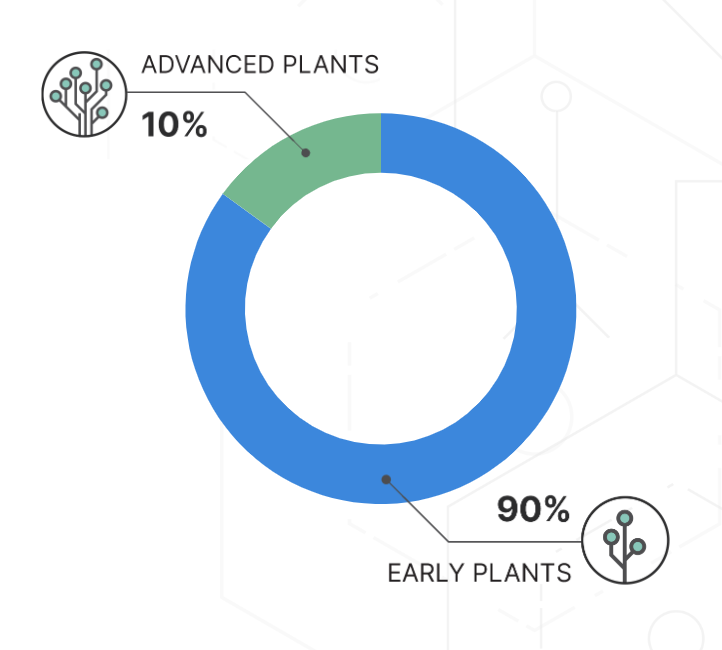

Vineet cautioned against the tendency to chase novelty before mastering consistency. Many companies have one or two world-class plants surrounded by dozens that lag behind. He called it the problem of “islands of excellence in an ocean of waste.” The solution is not to add more technology but to scale what already works.

True transformation is not about inventing new tools; it is about institutionalizing the behaviors, metrics, and governance that sustain excellence across the network. The most progressive manufacturers standardize how improvement happens, the cadence of reviews, the definitions of loss, the accountability loops that tie results to financial performance. Once that backbone exists, innovation can scale rather than scatter. AI will not save a broken system, but it can accelerate a disciplined one.

The age of AI will reveal the true manufacturing leaders. It rewards those who combine digital curiosity with financial literacy, and those who can interpret complexity through the lens of value. The future of manufacturing leadership belongs to people who understand that technology amplifies human intent, it does not substitute for it.

As Vineet concluded, excellence at scale is not a technical achievement; it is a leadership mindset. When organizations align around visibility, capability, and trust, they turn data into clarity, clarity into speed, and speed into enterprise value.

| Advisors Series: Turning Manufacturing Into Enterprise ValueHear how former leaders from P&G, Nestlé, and BASF turn manufacturing performance into enterprise value.

|

You might also enjoy: