Harnessing the Power of Learning and Technology for Successful Industry 4.0 Implementation

Industry 4.0, the fourth industrial revolution, is reshaping the business landscape with its advanced technologies and interconnected systems. To fully embrace the opportunities presented by Industry 4.0, organizations must develop an enterprise-wide strategy that integrates learning, aligns top-down and bottom-up approaches, focuses on value creation, and eliminates manufacturing losses. By connecting these key elements, organizations can unlock the true potential of Industry 4.0 and drive success in the digital age.

Aligning Strategy and Learning:

Developing a comprehensive Industry 4.0 strategy requires a seamless alignment between the strategic vision of top-level executives and the operational realities faced by frontline workers. By involving employees at all levels in the strategy development process, organizations foster a sense of ownership and commitment. This alignment ensures that learning initiatives are targeted and relevant, equipping employees with the skills and knowledge needed to thrive in the Industry 4.0 landscape.

Value Creation and Manufacturing Loss Elimination:

A successful Industry 4.0 strategy should focus on delivering value and eliminating manufacturing losses. By leveraging advanced technologies and data-driven insights, organizations can optimize processes, enhance product quality, reduce time to market, and offer personalized customer experiences. Integration of learning initiatives empowers employees to identify areas for improvement, participate in continuous improvement initiatives, and drive value creation throughout the entire value chain.

Continuous Improvement and Learning:

An enterprise-wide Industry 4.0 strategy should foster a culture of continuous improvement and learning. Learning initiatives play a crucial role in upskilling employees, optimizing processes, driving innovation, and enabling effective change management. By integrating learning programs that enhance technical proficiency, foster creativity and problem-solving skills, and promote collaboration, organizations empower their workforce to embrace change, drive improvement, and contribute to the success of Industry 4.0 initiatives.

Integration of Learning for Industry 4.0 Success:

In the context of continuous improvement and learning, integrating learning initiatives becomes a critical element for the successful implementation of an Industry 4.0 strategy. Here's how the integration of learning enhances the continuous improvement and learning aspect of the strategy:

Learning for Skill Enhancement:

Industry 4.0 brings forth advanced technologies that require specialized skills. By integrating learning programs, organizations can provide targeted training to upskill employees in areas such as data analytics, robotics, cybersecurity, and machine learning. These programs enable employees to stay updated with the latest technological advancements and contribute effectively to continuous improvement initiatives.

Learning for Process Optimization:

Learning plays a vital role in enabling employees to identify and implement process optimization measures. By offering training in lean manufacturing, Six Sigma, and other process improvement methodologies, organizations can equip employees with the tools and techniques to identify waste, reduce inefficiencies, and enhance productivity. Learning fosters a mindset of continuous improvement and encourages employees to proactively seek out opportunities for optimization.

Learning for Innovation and Creativity:

Industry 4.0 thrives on innovation and creativity. By integrating learning programs that focus on fostering creativity, problem-solving, and critical thinking skills, organizations can cultivate an innovative mindset among employees. Training in design thinking, ideation techniques, and innovation management empowers employees to contribute ideas and drive innovation in products, processes, and business models.

Learning for Change Management:

Industry 4.0 implementations often involve significant organizational changes. Learning initiatives can encompass change management training to help employees adapt to new technologies, processes, and ways of working. By providing resources and support for learning, organizations ensure that employees understand the reasons for change, are equipped with the necessary skills, and embrace the changes positively. Learning facilitates smooth transitions and minimizes resistance to change.

Learning for Collaboration and Cross-functional Integration:

Industry 4.0 requires cross-functional collaboration and integration of diverse expertise. Learning programs that focus on team building, communication, and collaboration skills help break down silos and foster a culture of cooperation. By providing opportunities for employees to learn and understand the perspectives of different functions, organizations enable effective collaboration and knowledge sharing, driving continuous improvement initiatives across departments.

Leveraging Technology with SmarterChains for Alignment and Empowerment:

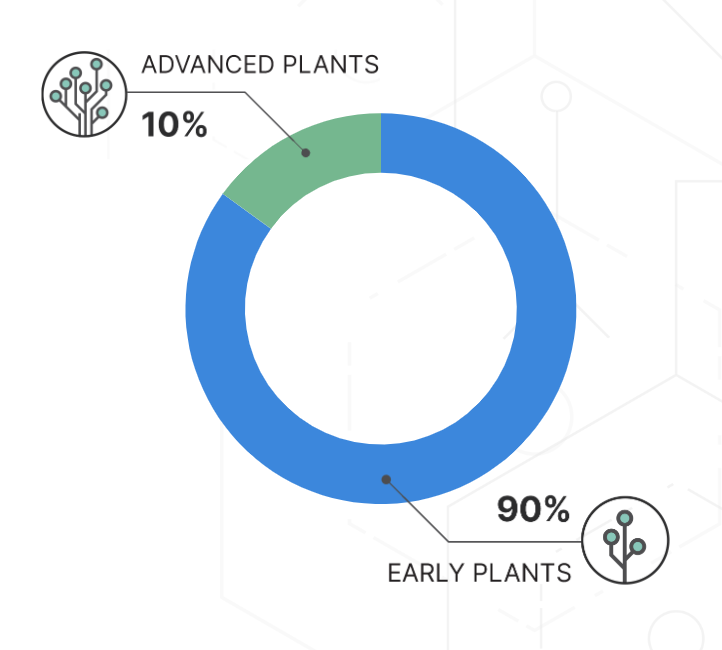

In the digital age, technology plays a pivotal role in enabling alignment and empowering employees. Platforms like SmarterChains provide self-serve tools that facilitate alignment across the organization. This user-friendly interface allows employees at all levels to contribute to the Industry 4.0 strategy, promoting engagement and collaboration. Furthermore, these platforms leverage real-time data analytics, predictive modeling, and machine learning to rapidly improve future plant performance, reducing manufacturing losses, and driving continuous improvement in operational excellence.

Conclusion:

In conclusion, the integration of learning into an enterprise-wide Industry 4.0 strategy is vital for organizations aiming to thrive in the digital age. By aligning learning initiatives with strategic objectives, organizations can equip their workforce with the necessary skills, foster a culture of continuous improvement, and drive value creation while eliminating manufacturing losses. Additionally, the use of innovative platforms like SmarterChains further enhances the alignment and empowerment within the organization.

The SmarterChains platform serves as a self-serve tool that enables seamless alignment across the organization. It provides a user-friendly interface that allows employees at all levels to access and contribute to the Industry 4.0 strategy. This self-serve capability promotes engagement, ownership, and collaboration, enabling a comprehensive and integrated approach to strategy execution.

Moreover, the SmarterChains platform empowers manufacturing and consulting teams to rapidly improve future plant performance in a matter of hours. By leveraging real-time data analytics, predictive modeling, and machine learning capabilities, the platform identifies optimization opportunities, streamlines processes, and enhances decision-making. The platform's agility and speed enable organizations to respond quickly to changes, reduce manufacturing losses, and achieve continuous improvement in plant performance.

By integrating the SmarterChains platform into the Industry 4.0 strategy, organizations can harness the power of technology to drive operational excellence and gain a competitive edge. The platform's self-serve capabilities and data-driven insights empower employees to actively contribute to the strategy, enabling efficient collaboration and knowledge sharing. With the ability to improve future plant performance in a matter of hours, organizations can achieve rapid and tangible results in their Industry 4.0 journey.

In conclusion, the integration of learning, coupled with innovative platforms like SmarterChains, enhances the alignment, engagement, and empowerment within organizations. This integration drives value creation, eliminates manufacturing losses, and accelerates the realization of the full potential of Industry 4.0. By embracing a holistic approach that incorporates learning, technology, and continuous improvement, organizations can successfully navigate the digital transformation and secure long-term success in the dynamic and interconnected Industry 4.0 landscape.

| Discover Untapped Potential in Your Manufacturing ProcessPrepare, define, and execute the Industry 4.0 strategies at scale.

|

You might also enjoy: